Unconventional methods in brake technology, moving past traditional magnetism

**Beyond Magnetism: The Future of Automotive Braking Systems**

The automotive industry is gearing up for a significant shift in brake technology, moving away from traditional mechanical brakes towards more innovative, efficient, and sustainable solutions – a transformation aptly named "Beyond Magnetism".

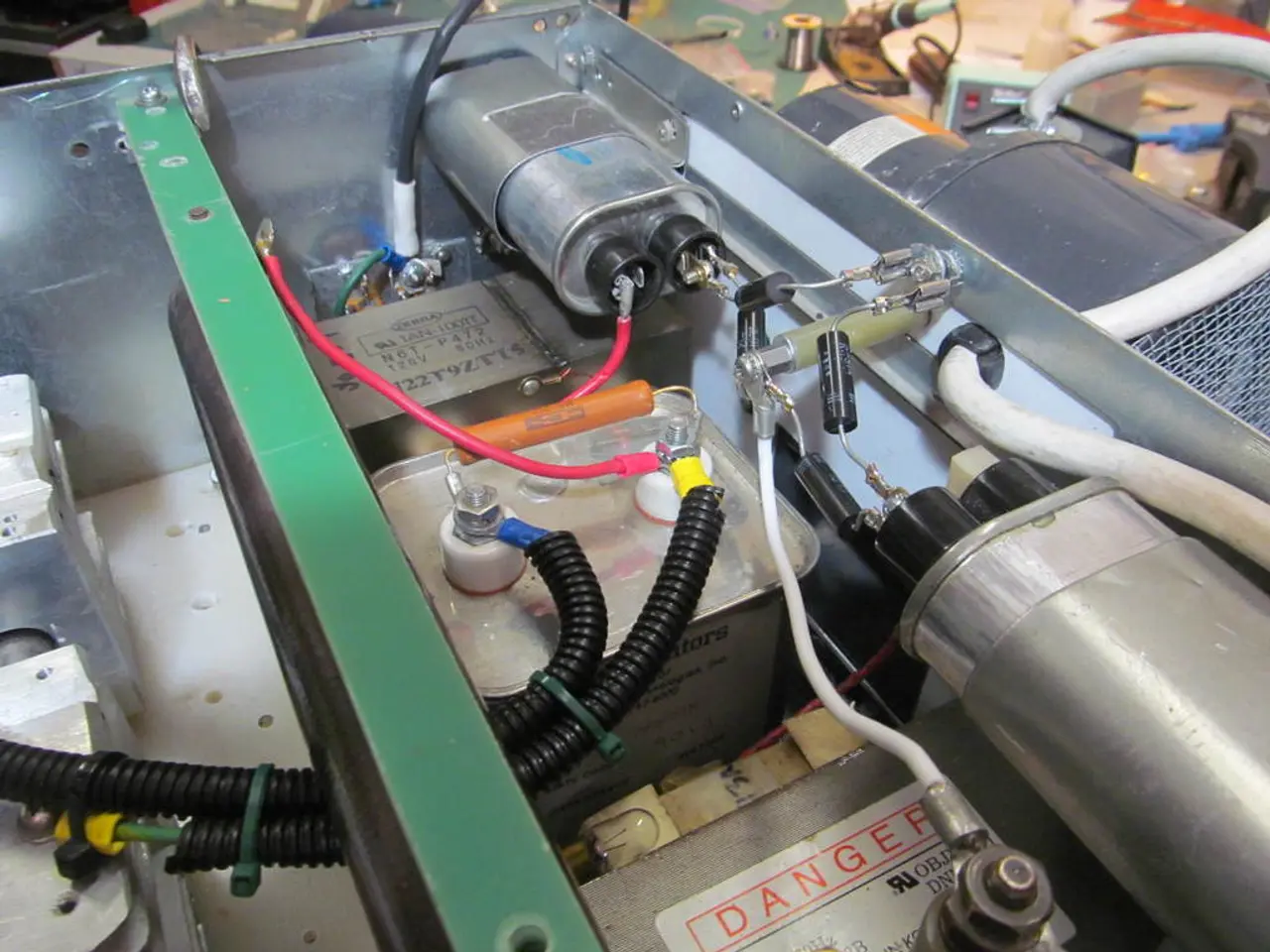

Current advancements in brake technologies are paving the way for this revolution. Companies like ZF are commercialising Electro-Mechanical Brake Systems (EMB), replacing traditional hydraulic brakes in millions of vehicles. These systems offer more precise modulation, redundancy, and the potential for autonomous driving compatibility.

Another development is the integration of hybrid braking systems, which combine electro-mechanical rear brakes with traditional hydraulic or hybrid actuation methods. This approach enables a smoother transition and scalable adoption of advanced brake technologies.

Innovations are not just limited to hardware improvements. Artificial Intelligence (AI) and control systems are playing an increasingly crucial role, with AI-enhanced ABS systems that can anticipate grip loss before wheel lock happens, optimising braking performance dynamically. Smart braking control algorithms and AI integration make braking responses more predictive, personalised, and energy-efficient.

Regenerative braking enhancements are also on the horizon. Future electric vehicle (EV) motors will have novel winding configurations and magnetic materials enabling higher power density and more aggressive regenerative braking without efficiency losses. Advancements in battery technologies support the efficient absorption of braking energy, maximising energy recovery.

Beyond Magnetism takes these advancements a step further. It envisions a future where brakes will employ new materials and motor configurations to enhance energy conversion and control during braking. This could lead to lighter, more efficient brakes that harvest more kinetic energy or provide more precise modulation.

The shift towards Beyond Magnetism also means a reliance on AI and machine learning, predicting braking events based on real-time data such as traffic conditions and road topology. This could optimise regenerative braking and energy recovery, reduce wear on components, and improve safety.

The brake industry is evolving towards software-defined performance improvements and electric actuation. Market growth is driven by electronic control units and actuators, with brake pads evolving to meet environmental standards (e.g., copper-free formulas). Beyond Magnetism suggests a trajectory towards fully integrated electrification and autonomous-function-compatible systems.

Brake innovations that focus on energy recovery efficiency (regenerative braking) combined with AI could significantly extend EV range and brake component life, contributing to sustainability and lower total cost of ownership.

In essence, Beyond Magnetism represents a holistic transformation from magnetic and purely mechanical components towards electro-mechanical, software-driven, and energy-efficient systems that tightly integrate with vehicle electronics, AI, and energy storage technologies. This evolution promises significant benefits in braking performance, energy efficiency, safety, and sustainability.

- The future of automotive braking systems, as envisioned in "Beyond Magnetism," incorporates the use of new materials and motor configurations, which can enhance energy conversion and control during braking, leading to lighter, more efficient brakes that harvest more kinetic energy.

- The advancements in the brake industry are not only limited to hardware improvements, but also involve the integration of Artificial Intelligence (AI) and control systems, with AI-enhanced ABS systems that can anticipate grip loss and optimize braking performance dynamically.

- As the automotive industry shifts towards electro-mechanical, software-driven, and energy-efficient systems that are tightly integrated with vehicle electronics, AI, and energy storage technologies, the market growth is driven by electronic control units and actuators, with brake pads evolving to meet environmental standards, such as copper-free formulas.