Understanding the Process of Electronic Circuit Simulation

In the realm of electronic design, circuit simulation plays a crucial role in ensuring the functionality and efficiency of circuits before they are manufactured and deployed. This article will delve into the process of circuit simulation, its various applications, and the key steps involved.

At its core, circuit simulation is a mathematical modeling of electronic circuits. It involves formulating circuit/network equations and solving these equations to understand the behavior of the circuit. This process is essential for verifying the design's correctness and preventing costly rework during the production phase.

One of the most popular open-source circuit simulation engines is SPICE (Simulation Program with Integrated Circuit Emphasis). LTspice®, developed by Analog Devices Inc., is another similar software. These tools accept a netlist describing the circuit for various simulations.

Pulse input analysis in LTspice® allows for the observation of voltage and current changes in the circuit over time, while DC analysis can be performed to determine input and output levels. AC analysis can be used to study circuit behavior at different frequencies, and transient analysis is a method used to study electrical circuits during their transition from one steady-state condition to another.

For digital circuits, the simulation process includes using circuit behavior models generated using hardware description language (HDL). The IBIS model, for instance, details the electrical characteristics of the digital inputs and outputs of a device, used for signal integrity analysis on systems boards.

The circuit simulation process for electronic circuit designs involves several key steps. First, the circuit's purpose, operating conditions, and performance criteria are defined to establish design goals (Requirement Analysis). Then, the circuit schematic is created by placing components and connecting them logically (Circuit Design and Schematic Capture).

Next, for digital/ASIC designs, functional or behavioral descriptions are translated to a gate-level netlist using logic synthesis tools (Logic Design and Synthesis). Design constraints such as clock frequency, power targets, and timing requirements are specified to guide simulation and synthesis tools (Constraint Definition and Setup for Simulation).

Functional simulation is then performed to verify the logical correctness, followed by timing simulation to validate delays and timing behavior under expected signal conditions. This includes pre-layout and post-layout simulations for analog/digital and mixed-signal circuits (Simulation).

Verification is a critical step, using formal verification, test coverage analysis, and fault simulation to ensure the design meets specifications and checks for errors or inconsistencies between RTL and synthesized netlist.

After successful simulation and verification, the design proceeds to physical design steps like placement, routing, and extraction of parasitics that affect performance, followed by post-layout simulation for final validation. Design rule checks (DRC), layout versus schematic (LVS) verification, and power/timing analysis are performed to ensure manufacturability and compliance (Rule Checking and Final Validation).

Finally, test vectors are generated for automatic test equipment (ATE) and data prepared for fabrication and further testing stages (Generation of Test Patterns and Preparation for Fabrication).

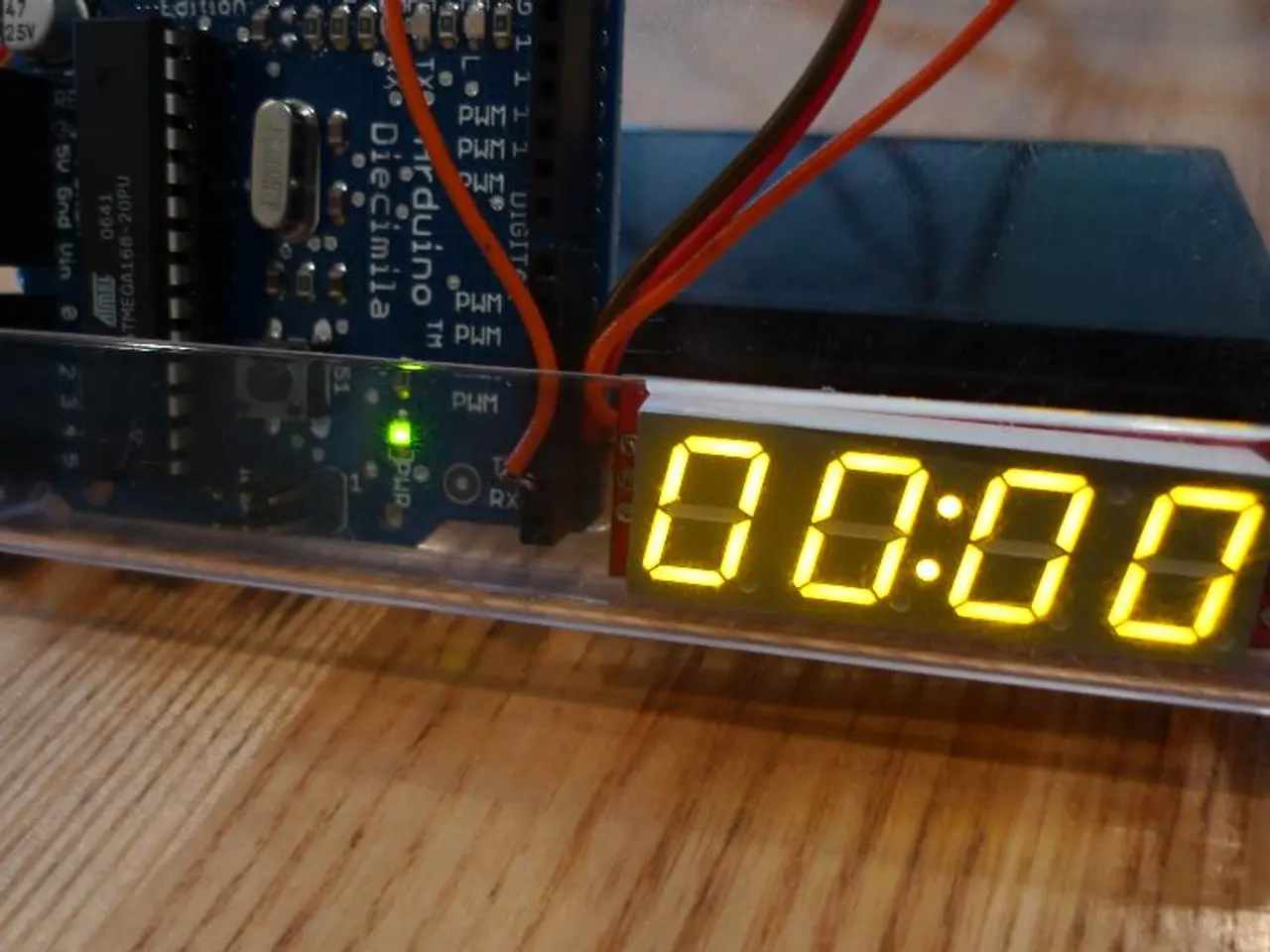

Circuit simulation is a valuable tool for PCB designers, helping to understand circuit behavior before board fabrication and preventing expensive PCB rework and design inefficiencies. It is used for a broad range of applications, including microelectronics, integrated circuits, power electronics, and electrical power distribution networks.

Understanding circuit simulation is essential for any electronic design engineer. By simulating circuits, engineers can ensure their designs are efficient, reliable, and meet the required specifications before they are manufactured and deployed.

Controlled impedance technology plays a significant role in circuit simulation, particularly for PCB designs, as it ensures consistent electrical characteristics throughout the printed circuit board, improving overall circuit performance.

In the realm of circuit simulation, various technologies, such as SPICE and LTspice®, are employed to model and analyze electronic circuits, helping engineers design efficient, reliable, and specified circuits before their physical realization.